How do Digital Factory and Kraftwurx fit together? That's an easy question to answer. Digital Factory powers the Kraftwurx website - as a customer.

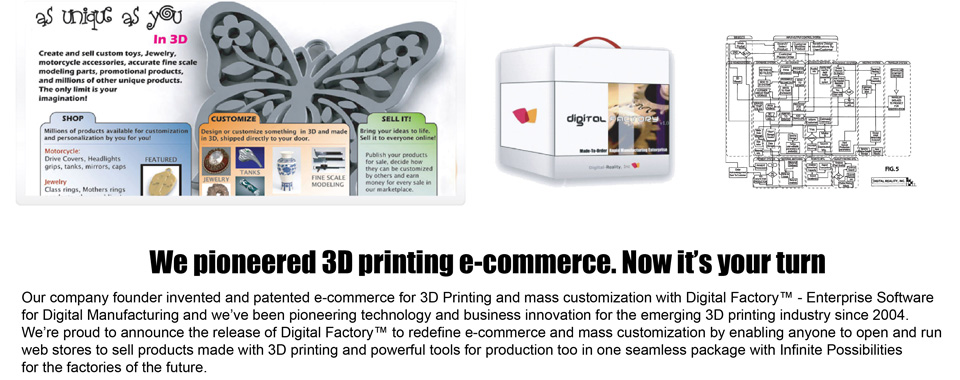

We started working on the Digital Factory system in 2004 - we've been developing and improving our technology ever since. While other companies have been vocal about bringing 3D printing to the markets, we've been commercializing technology that we patented in 2006.

In 2006 we published an online Demo for Digital Reality, mass customization with 3D printing. Of course that was after we filed patent protection for our business model: Made-To-Order Digital Manufacturing Enterprise. US Patent 8,515,826 and patents pending protect our business model for Digital Factory.

Kraftwurx launched in November 2011 with the goal of printing the planet. When we launched, the site was already running an efficient backend system that effectively manages the manufacturing operations. That product is called Digital Factory and it is essentially an Enterprise Resource Planning System, purpose built for 3D printing.

Digital Factory is responsible for order management, shipping, supply chain management, planning...basically it runs the show. This ensures that what we ship arrives at your door correctly, including guaranteeing that you don't get somebody else's shipment. This is a problem we hear often about our competition.

Managing the volume of orders in a website like Kraftwurx is a daunting task but Digital Factory from Digital Reality makes things very easy. It is essentially a plug and play system. But it continues to evolve.

Digital Factory emerged from my personal career and education in manufacturing and engineering, working for companies like Dell in product development and Applied Materials making semiconductors (computer chips). I am also a 16 year member of the Society of Manufacturing Engineers and a member of the Direct Digital Manufacturing tech committee which is part of SME's RTAM community or Rapid Technologies and Additive Manufacturing.

My career included lots of operations work and coupled with a deep love of 3D rendering and Animation. I did my first render on a Mac LC II in 1991 using a program called Infini-D 1.0. I quickly moved to Electric Image and Ray Dream Designer. You name it and I have used the app for CAD or rendering.

By 2004 I had begun formulating ideas for Online Customization of products via 3D and rapid prototyping. I watched my then 12 year old son Austin playing a game called Midnight Club where you can customize your car and then drive it. My son I noticed, spent more time customizing than driving and constantly wanted to show off his designs. Digital Factory became an obvious thing to build. It Did not come about overnight, it gelled over the course of about 4 years, starting with seeing websites like VistaPrint and a now defunct site called Customatix or cmax. CMAX was the precurser to NikeID and was very innovative.

By 2007 I was pitching the idea to VC's in Austin, the Austin Technology Incubator and the Texas Emerging Technology Fund. It was an exciting time and there was nothing even remotely like it at being demonstrated. In late 2007 Someone posted an article about me and the system on Makezine, Make Magazines website. Shortly afterward I received more calls from made for one and even Derek Kelley at ponoko who was doing laser cutting. It was an interesting time...then we went dormant, working on our system.

The future of Digital Factory is promising. The growth of 3D printing or what I prefer to call Digital Manufacturing will only accelerate in coming years. Its growth fueled by the minds of innovative entrepreneurs and inventors.

Some people and indeed companies think they will lock up this emerging market and position themselves to control it...I think that is naieve. It's going to go viral, grow in ways that we don't understand yet. In ten years, 3D printing will have just become a serious contendor for the manufacturing real goods, not Just novel's items. For this change to occur, prices must drop, materials must improve and software tools must evolve so that its easy to take advantage of all the possibilities offered by the technology. It's an area that we hope to play in and bring these tools to you through Digital Factory and Kraftwurx.