In 2004 I has just left working at the Artcarved Balfour jewelry company for Dell as the Wireless product development manager for all notebook wireless products. Much better pay, great company and very dynamic environment. Still, I had this idea brewing around customization in a website that a friend of mine Chad Oliver and I had been talking about. Then, one Saturday afternoon I was wathing my son Austin play Midnight Club on the Playstation 2 and I had an Epiphany - create a way for consumers to use CAD to modify base designs freely, affecting the geometry itself and printing the results using 3D Printing. Of Course I was thinking about Class Rings because they were so unique and each order required a completely different set of parameters but, it didn't take long for the idea to grow...

What occurred tome was that the psychology of consumers as designers would translate from websites like Dell who used this business model lure customers into buying from them online. People simply want what they want and companies around the world want to meet their customers needs but the best technology around at the time were "Configurators" and a few specialized websites like Vista Print which in my humble opinion was a very early pioneer in online personalization. The idea behind personalization was powerful and between 2001 and 2004 I saw the emergence of websites like Zazzle and Cafe Press.

One website that stood out to me was a company called Customatix or Cmax. They were a shoe company offering the ability to personalize shoes online. You could even upload your own sole art that would be printed and embedded behind a clear rubber sole. They were way before NikeID but their timing and product designs were inferior and the company faded away. The idea stuck with me though.

As I investigated how to do CAD in a browser, I was able to gain resources that most could not working at Dell. It became apparent all too quickly that there weren't many options available to accomplish my goals. ActiveX in Internet Explorer was one option but restricted to Explorer. Another option was the Viewpoint Media Player. I also tried edrawings. All of these options required plugins to be installed on the local computer. None of them was robust and none had any hope of accomplishing what I needed so, I focused on timing the product and shifted gears toi protecting my ideas. My research eventually led me to another conclusion- ecommerce solutions for the business model would not meet the requirements of ecommerce needs for on-demand digital manufacturing. This was something everyone agreed upon in the industry like Terry Terry Wohlers and Todd Todd Grimm.

I was attending graduate school for my MBA in 2005 and wrote a business plan for the development of a new kind of ecommerce platform, built specifically for 3D Printing and Mass Customization. Nobody referred to SaaS or PaaS in those days so the embodiment was a box software package you buy and install. The product became named Digital Factory.

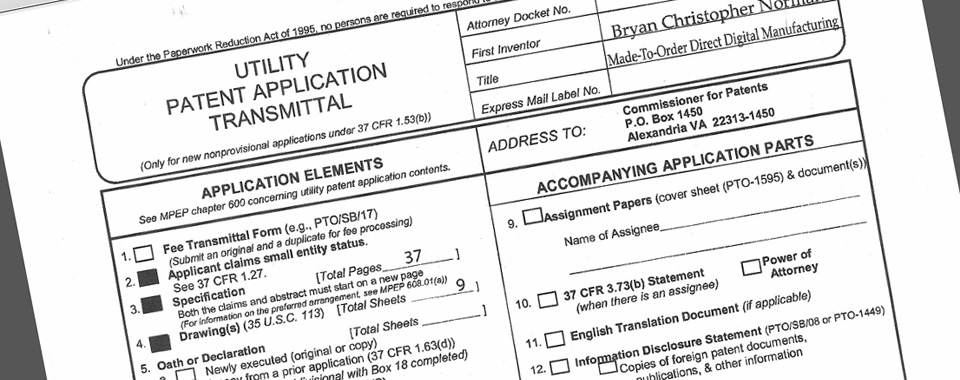

In 2005, I retained Don Jarrell to help begin writing a provisional patent application entitled Made-To-Order Digital Manufacturing Enterprise. The name made sense because it embodied the concept for making products on demand from 3D Printing and tge wird Enterprises symbolized a product for sale to businesses. As a Manufacturing engineer it made sense because we were used to software called ERP or enterprise resource planning and MRP materials resource planning from systems like agile and Oracle. Tbese Enterprise software solutions were commercially available bytvthey were in no way ready for the 3D Printing based manufacturing process.

In May 2006, I filed a provisional patent application for a utility patent Entitled Made-To-Order Digital Manufacturing Enterprise after the products namesake. The provisional covered everything including products that can be made with 3D printing. Just after filing, I flew to Chicago to attend RAPID where I met Todd Grimm, Terry Wohlers and others. I even disclosed a great deal of our business and patented information with several people including Todd Grimm but did not with Terry Wohlers (sorry terry).

That same year, I formed a company called Digital Reality, Inc. I raised some money and published a demo. By 2007 we converted the provisional patent to an actual patent and began to see press coverage from several sources including Make Magazine and Made for One. You can still find that demo today. It why is admittedly crude but it got the point across. It looks like simply a website offering products made with 3d printing but in reality it was a demonstration of the business model in the patent for a commercial product to create websites like this.

The next couple of years I will find the business model prosecuted patents and formulated a few strategic partnerships. In 2009 I was contacted by Leslie Langnau of Make Parts Fast for an interview. Her article entitled the shape of things to come compared Digital reality to shapeways. Which we were completely unaware of. That article led us to contact shapeways in 2009 asking them to collaborate with us and to let them know about our 2006 Patent. I never heard from them at all so I assume that they were uninterested but we continue to press forward on our technology and Patent.

In August 2011 the assets including the Patent of Digital Reality were acquired by Kraftwurx and we launched our website in November of the same year. If you pay attention near the top of the web page for Kraftwurx you'll see a note that says powered by Digital Factory. We used Kraftwurx.com as a prooving ground for Digital Factory. The business model in our patent.

The purpose of the story is to correct some mis quotes in other articles. The bottom line is that I came up with tge business idea in 2004, patented it in 2006 and have been pursuing this business model for some time.

It felt like timing was right to launch Digital Factory this year. The 3D Printing industry is well publicized, many companies are at various stages of trying to start businesses using the basic business model and the financial sector is looking for real use because the hype cycle is over - they want real examples of use and real profits. This is a great Segway into our mission at Kraftwurx.

Digital Factory from Kraftwurx is the embodiment of Our intent to bring to market, software and services to allow anyone to start and run an ecommerce website selling 3D Printing products and tools to manage your manufacturing operations with your printers or ours.

The best way to think of Digital Factory is like a mahup of Shopify- a web store solution for 3D Printing, NikeID style customization capabilities and manufacturing software like Oracle but made for 3D Printing. Let's face it to start a business in 3D printing you either buy a bunch of different software and stitch it together for your needs or start from scratch and build it yourself. Both are expensive and time consuming and yes there are land mines along the way you'll discover.

We feel consumers want what THEY want not just ten thousand choices of 3D printed designs but rather ways to tweak a few designs to make it personal.

With prices starting at $49.99 per month, we're making our platform availed at prices that are affordable for virtually everyone. Our development road map is built around you. We will continue to add features everyone will benefit from without additional expense. Right now we've got quite a bit to offer you:

1. Pro-Quote is our upload and quote engine for your website. Accept credit cards, PayPal and even Purchase Orders for registered users you qualify!

2. Asset Management tools for your 3D Models.

3. Analytics to help you track your monthly sales.

4. Easy export of your financial situation and integration for accounting programs like Quickbooks, Quicken and others.

5. Facebook stores- open unlimited pages and sell on Facebook.

6. Kiosk technology for in store sales, file upload and customization.

7. Turnkey ecommerce templates let you get started in minutes. Integration with popular Content Management Solutions like WordPress and Joomla.

8. Social Media Integration to drive sales virally and awareness.

9. Franchise capabilities to sub license our platform for your brand.

10. Customization technology built for consumers. We're making it easy for you to offer your customers a compelling competitive advantage online for sales.

11. Amazing visualization technology is coming soon.

12. Easy to use dashboards for managing your printers, materials and orders as a bureau using your printers or order management with our printers.

13. Easy shipping. Click, print, ship. Generate shipping labels with many common carriers quickly and easily.

14. Advanced Patented serial part marking technology called Digital Traveler. Each part carries part marking technology so you don't confuse orders.

15. Automated part nesting, stacking and routings.

16. Bills of Materials.

17. Part routings for post processing operations.

18. Assemblies-yes, multi part assemblies with individual part materials in the assembly. An industry first.

19. More technology and tools like thin wall detection, dynamic pricing, much more.

We exist to Empower the 3D Printing Revolution through your business and bring to market true consumer products made with 3D Printing.

What can we do for you?

Sent from my Sprint Samsung Galaxy Note5.